Supreme Rolls & Shears Pvt. Ltd. has truly carved out a reputation as a pioneer in Cold Rolling Mill Roll manufacturing, and their process reflects a commitment to precision and quality at every stage. Here's a refined overview of what sets them apart:

End-to-End Manufacturing Excellence

- Raw Material Inspection: Rigorous quality checks ensure only premium-grade alloys are used.

- Proof Machining: Early-stage machining guarantees dimensional accuracy before final shaping.

- Advanced Heat Treatment: In-house facilities allow precise control over hardness and metallurgical properties, enhancing wear resistance and longevity.

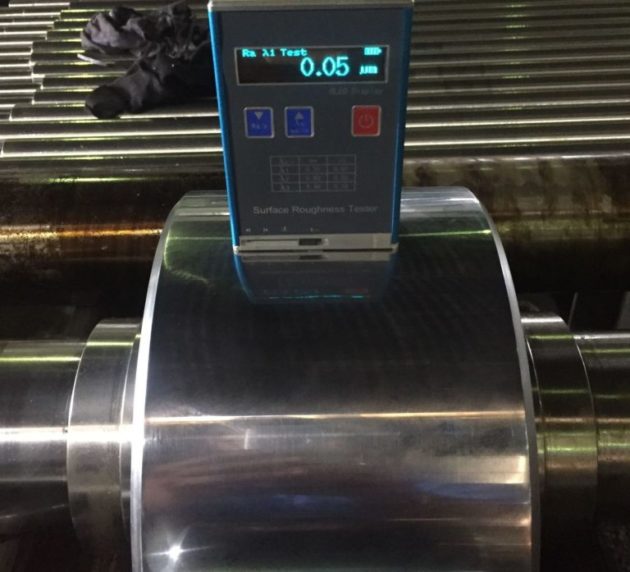

- Precision Grinding: Delivers smooth surface finishes and tight tolerances, crucial for high-speed rolling operations.

- Final Inspection: Comprehensive testing ensures each roll meets stringent performance standards. (Testings includes Ultrasonic testing, DP Test, MPT Test)

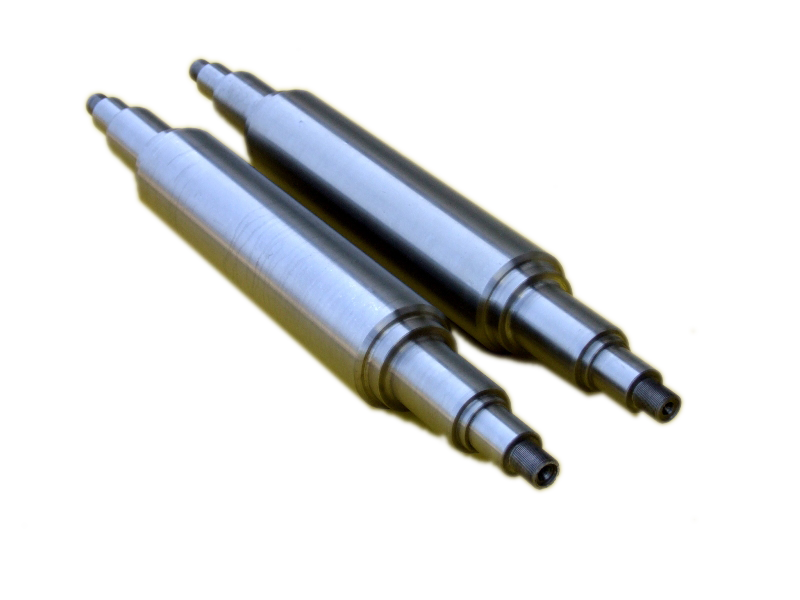

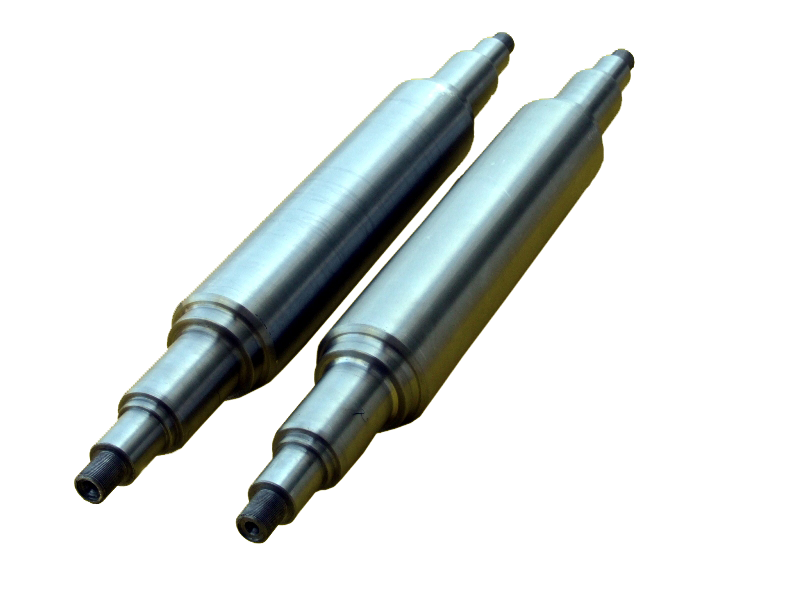

We manufacture hardened & ground rolls required by cold rolling mills which are suitable for rolling mild steel, stainless steel, copper, brass, aluminium and other materials in sheet or coil form. These CRM Rolls can be used in 2Hi, 4Hi, 6Hi, 12Hi, 20Hi (Sendzimir) mills. We convert discarded large diameter rolls to finished smaller diameter rolls for variety of applications, along with re-sleeving of backup rolls.

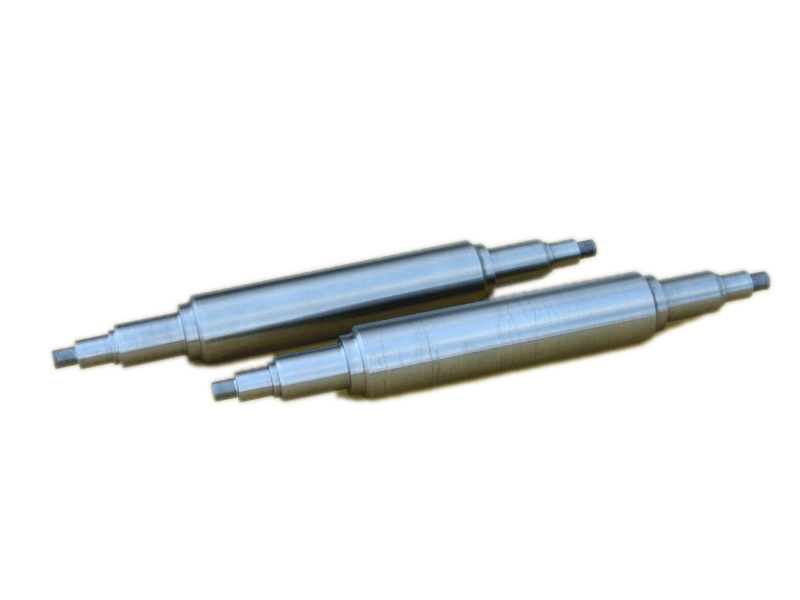

- Sendzimir Mill (20Hi) Rolls

- Work Rolls

- Intermediate Rolls

- Drive Rolls

- Idler Rolls

- Backup Sleeves

- 2Hi, 4Hi, 6Hi, 12Hi Mill Rolls and others

- Work Rolls

- Intermediate Rolls

- Backup Rolls

- Sleeves