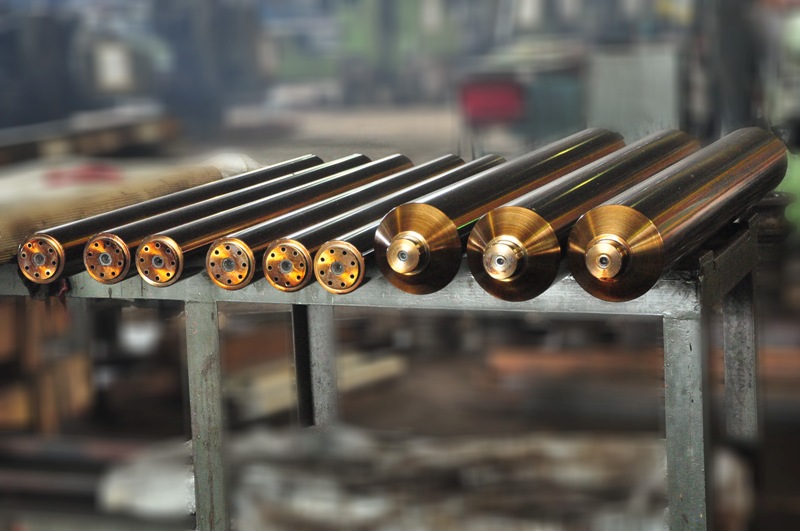

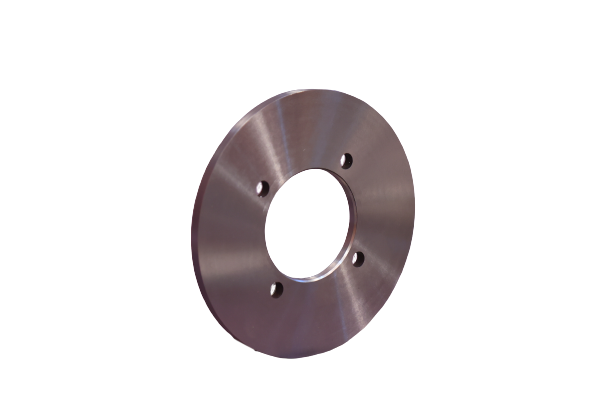

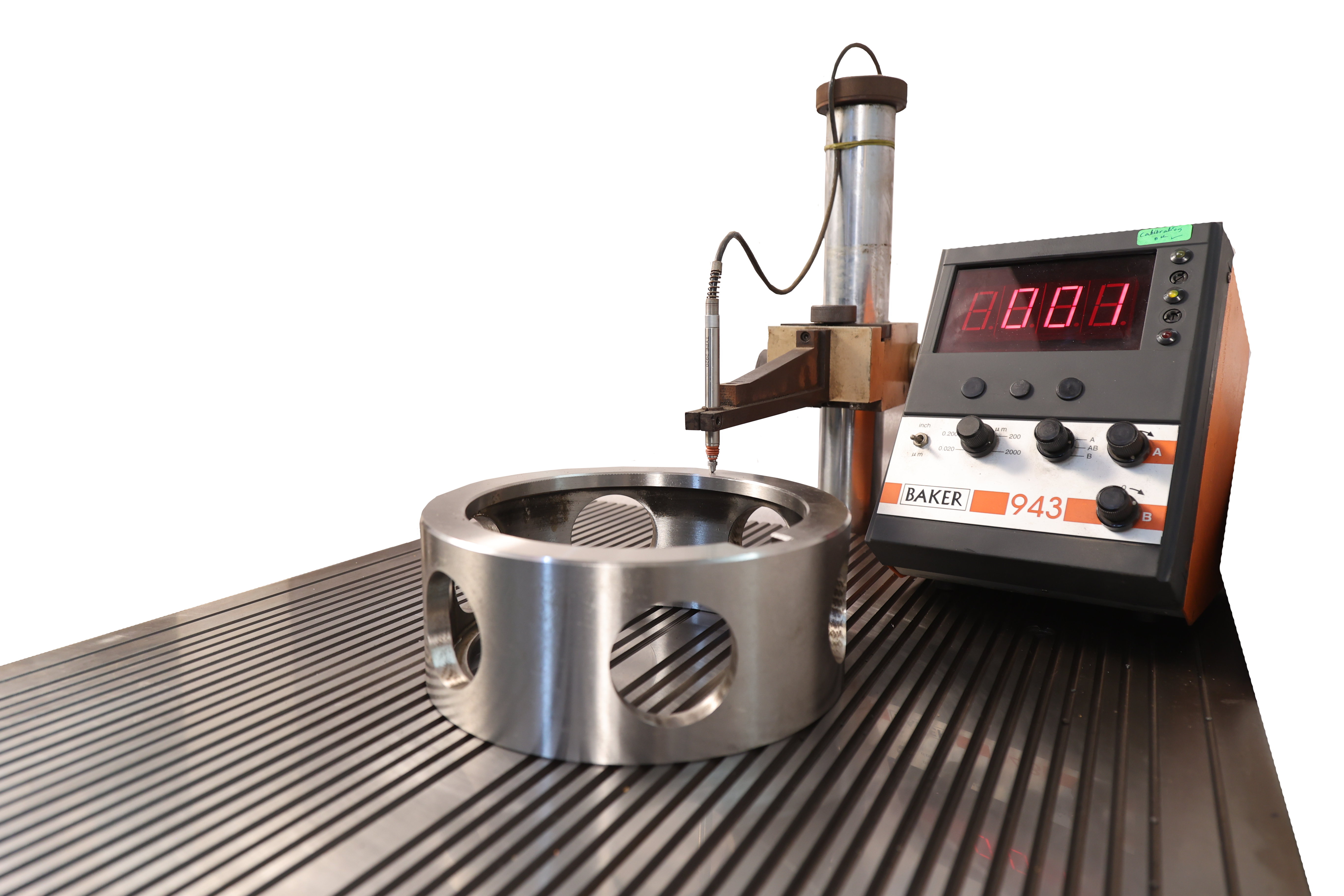

Advanced Manufacturing Facility:

Our expansive production unit is equipped with cutting-edge machinery, including CNC machining centers, precision grinders, heavy-duty lathes, and automated milling machines. This enables us to produce complex and large-scale components with unmatched precision and consistency.