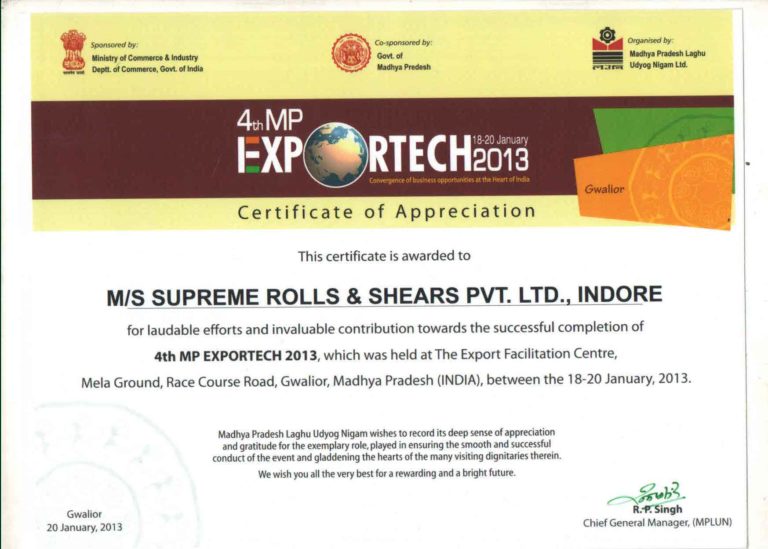

- ISM Certificate Manufacturer

At Supreme Rolls and Shears Pvt. Ltd., we are a trusted name in the industrial metal processing industry, known for our expertise in manufacturing high-quality Cold Rolling Mill Rolls, Slitting Line Tooling, Shear Blades, and more. With decades of experience, we serve industries worldwide, providing precision-engineered solutions that meet the most demanding standards. Our commitment to innovation, quality, and customer satisfaction drives us to deliver excellence in every product we manufacture. As a leading manufacturer, we take pride in our cutting-edge technology and the skilled workforce that supports our mission to enhance industrial efficiency and performance globally.

It all started at the dawn of the 21st century in the year 2000 when Supreme Rolls and Shears Pvt. Ltd. Supreme was incorporated as a Private Limited company engaged in manufacturing of different types of industrial metal processing tools. Since our inception in 2000, supplying quality products to our customers has been our topmost priority. We manufacture products of utmost quality by understanding their usage and the application. The fact that our customer base has been constantly growing speaks volume of the quality and service we provide to our customers.

Supreme Rolls and Shears Pvt. Ltd. is a leading manufacturer of industrial metal processing tools, dedicated to delivering high-quality products tailored to the needs of our clients. Our extensive product range includes:

Cold Rolling Mill Rolls (CRM Rolls)

Leveller / Straightening Rolls

Slitting Line Tooling

Tube Mill / Section Forming Rolls

Shafts and Arbours

Shear Blades

Industrial Machine Knives

To be the global leader in precision-engineered industrial metal processing tools, setting the benchmark for quality, innovation, and customer satisfaction. We strive to empower industries worldwide by delivering superior solutions that enhance efficiency, durability, and performance in metal processing.

At Supreme Rolls and Shears Pvt. Ltd., our mission is to be a trusted global leader in the manufacturing of high-performance metal processing tools. We are committed to delivering precision-engineered products that enhance industrial productivity, ensure durability, and drive innovation in the metal processing industry. Through continuous improvement, advanced technology, and a customer-focused approach, we aim to provide tailored solutions that meet the evolving needs of our clients, while upholding the highest standards of quality, sustainability, and safety.

Skilled Workers

Engineers

Clientle

Export Countries

At Supreme Rolls and Shears Pvt. Ltd., we are committed to delivering superior value through quality, precision, and innovation. Here’s why our clients trust us as their go-to partner for metal processing tools:

Our investment in both traditional and advanced machinery allows us to offer flexible manufacturing solutions, ensuring that we meet the needs of industries with diverse requirements for precision, durability, and customization.

- deliver on time & on budget

- A dedicated service

Workshop Capabilities:

Custom Fabrication:

Our workshop’s combination of manual and CNC machines enables us to produce custom tools and components to exact client specifications.

Precision Engineering:

With state-of-the-art grinding, milling, and turning machines, we deliver precision-engineered solutions that meet the highest standards of accuracy.

Flexibility

Whether producing small batches or large-volume runs, our diverse machinery allows us to adapt to varying production requirements, ensuring timely delivery without compromising quality.

- deliver on time & on budget

- A dedicated service

Industry Leadership

Tailored Solutions

State-of-the-Art Manufacturing:

Durability and Performance:

As a leading manufacturer in the metal processing industry, we have set benchmarks for excellence, serving some of the most demanding industries with robust and reliable products.

We understand that each customer’s needs are unique. Our engineering team works closely with clients to develop custom solutions that align with specific applications, ensuring optimal performance in every project.

We invest in cutting-edge technology, modern machinery, and advanced manufacturing processes, ensuring that every roll, blade, and tool is crafted with the highest precision and efficiency.

Our products are built to last. Whether it’s Cold Rolling Mill Rolls or Industrial Knives, we focus on delivering tools that withstand the toughest environments and offer long-lasting performance.